Built up roofs have been a staple in the U.S. for over 100 years. They are known for their strong, multi-layered design. This design uses organic or fiberglass matting soaked in bitumen. This makes a solid membrane that protects well.

Adding gravel or stone on top makes these roofs even more durable. They also block UV rays, ensuring they last a long time. Their strength against the elements makes them a top choice for business and industrial buildings. They keep buildings warm or cool, depending on the weather.

Key Takeaways

- Built up roofs have over 100 years of utilization in the U.S.

- These multi-layer roofing systems consist of organic or fiberglass matting saturated with bitumen for robustness.

- Gravel or stone surfacing provides durability, UV protection, and stability.

- Commonly used in industrial and commercial buildings for their insulation and performance.

- Capable of withstanding challenging environmental conditions.

Introduction to Built Up Roof Systems

The Built-Up Roofing (BUR) system has been a key part of low-slope roofing for over a century. It’s popular because it has multiple layers that protect commercial buildings well. Understanding how BUR systems work is key in the U.S., where the weather varies a lot.

History and Development

More than 100 years ago, BUR systems started in the U.S. By the mid-to-late 1970s, most low-slope roofs were either asphalt or coal tar BUR roofs. Innovations like cold-applied BUR systems came later, using adhesives without solvents. This made them safer and better for the environment.

Now, BUR systems face competition from other low-slope roofing options that have come out in the last few decades.

Common Uses in Commercial Buildings

The BUR system is great for protecting commercial buildings. It uses multiple layers under a cap sheet or flood coat. These layers are perfect for low-slope roofs, keeping out water, handling temperature changes, and protecting against thermal shock.

Because of its insulation, buildings stay at a steady temperature. This saves energy and money. Plus, the deck can be made of concrete, wood, or steel, making BUR systems flexible for different commercial uses.

Benefits of Built Up Roofing

Built-up roofing (BUR) systems are a top choice for commercial buildings in North America. They are valued at over $700 million, showing their importance in long-term roofing. We’ll look at how BUR systems stand out in longevity, durability, energy efficiency, and insulation.

Longevity and Durability

BUR systems are known for their long life and strength. They are made by layering bitumen and reinforcing fabrics. This makes them strong against fire and wind, making BUR roofs very durable. BUR roofs can last 40 years or more with the right care, beating the 15-30 years of asphalt shingles.

For over a century, Built-Up Roofing has been a top pick for commercial buildings. It costs between $5.50 to $8.50 per square foot to install. This makes BUR a smart choice for saving money over time. It needs fewer repairs and replacements, cutting down on costs.

Energy Efficiency and Insulation

BUR systems also help make roofs more energy-efficient. They often have reflective cap sheets that bounce back the sun’s rays. This keeps the inside cooler, which can save on heating and cooling costs. Plus, the finishing materials on BUR roofs reflect UV rays, lowering energy use.

The insulation of BUR systems is key to saving energy. With many layers, BUR roofs provide better insulation. This keeps the inside temperature steady, helping commercial buildings use less energy and produce less carbon.

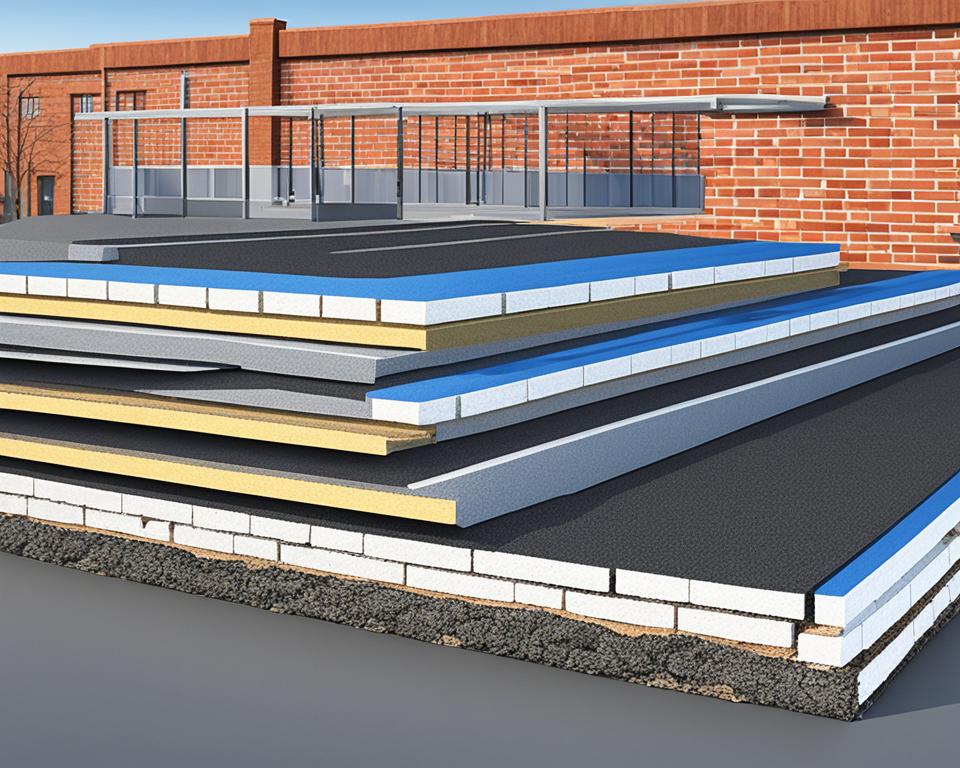

Components of a Built Up Roof System

Built-Up Roofs (BUR) are known for their reliability and versatility. Each layer of a BUR roof is crucial for its durability and effectiveness. For over a century, these roofs have shown their worth with their multi-layered design.

A typical BUR roof starts with a base sheet over insulation. This base sheet provides a solid base for the rest of the layers. Then, hot or cold asphalt layers are added to bond the other components together. These layers make the roof waterproof.

Next, multiple layers of roofing felts or ply sheets are applied. These felts form a strong membrane that boosts the roof’s waterproofing and strength. If the top layer gets damaged, the lower layers can still protect the building.

The roof finishes with a mineral-surfaced cap sheet or gravel covering. These surfaces shield the asphalt from the elements and UV rays. The gravel also makes the roof fire-resistant, which is important for commercial buildings.

However, BUR roofs have some downsides. Finding leaks can be hard because of their layered design. Regular checks and fixing any issues quickly are key to making the roof last longer. The roof’s life can be 15 to 40 years, depending on care and the climate.

Knowing about BUR components is important for those in commercial roofing. It shows the benefits and what needs regular upkeep.

Installation Process of Built Up Roofs

The installation of Built-Up Roofs (BUR) is a trusted way to protect commercial buildings. It covers the key steps in BUR installation. These include roofing preparation, ply sheet application, and asphalt roofing installation. Each step is crucial for a successful roof.

Preparation and Base Layer

First, the roof must be prepared for BUR installation. This means cleaning and priming the surface to remove dirt and other substances. A base layer, often a bitumen sheet, is then put down. This layer is key because it helps keep water out and supports the rest of the roof.

Getting this step right is important. It helps prevent water from getting in and keeps the roof stable over time.

Application of Ply Sheets

Next, the ply sheets are applied. These are layers of felt that are put down in a specific pattern. They are covered in asphalt or adhesive to stick together well. This makes the roof strong and waterproof.

This process makes the roof last longer with the right care. It helps the BUR roof last for many years.

After that, the layers are carefully put together and pressed to get rid of any air pockets. This is topped with a final layer of cap sheet or gravel. This makes the roof strong against water, fire, and different weather.

A good BUR installation takes careful planning from start to finish. It’s a solid choice for protecting commercial buildings.

Materials Used in Built Up Roofs

Built-Up Roofing (BUR) systems have been around since the mid-1800s. They are popular because of the variety of materials used. These include roofing membranes, asphalt, and fibreglass. Together, they make a strong and long-lasting roof.

The GlasBase Plus is a key layer in BUR systems. The GlasKap is often used as a top layer. GlasKap Plus adds SBS for better stretch and flexibility in cold weather. This mix makes the roof more durable and flexible, reducing the chance of cracks around vents.

Adhesives like the JM One-Step Foamable Adhesive hold insulation and boards in place. They keep the roof membranes strong, even with heavy water pooling. This is important because water can gather and cause problems, especially near vents.

For upkeep, the 19 Ultra rubberized asphalt cement and 502 SEBS mastics are good choices. The 229 SBS rubber reinforced asphalt and 670 silicone coating also work well. These products help fix common wear spots, especially where roofs meet vents.

Cleaning ponding areas is key to keeping BUR roofs in good shape. Getting rid of dirt and debris helps prevent damage. Regular upkeep and the right materials make BUR roofs last longer and work better in commercial settings.

Comparing Built Up Roofs to Other Roofing Systems

When looking at roofing system comparison, it’s key to consider the pros and cons of BUR versus single-ply systems. Each has its own benefits and challenges. The choice depends on what your building needs and its conditions.

BUR roofs can last up to 40 years with little need for repairs. In contrast, single-ply roofing, like TPO or EPDM, usually lasts 10-30 years. BUR is more cost-effective and durable, making it great for many commercial buildings.

From an asphaltic roofing options view, BUR has been trusted in the U.S. for over a century. It offers strong protection against the weather. Single-ply systems reflect sunlight to cut cooling costs but can get punctures, needing more upkeep.

For flat roofs, it’s important to see how each system holds up in bad weather. BUR is great at fighting fires and protecting against the weather. Single-ply stands up well to strong winds, heavy rain, and extreme temperatures, which is important for buildings in tough climates.

Here’s a detailed look at different roofing systems to help you decide:

| Feature | BUR (Built-Up Roofing) | Single-Ply Roofing | Modified Bitumen |

|---|---|---|---|

| Lifespan | Up to 40 years | 10-30 years | 10-20 years |

| Fire Resistance | High | Variable (up to Class A) | Moderate |

| Reflectivity | High Solar Reflectivity | Highly Reflective | Moderate |

| Weather Resistance | Excellent | High | Good |

| Installation | Professional | DIY possible | DIY possible |

| Cost | Cost-Effective Long term | Expensive | Inexpensive |

Choosing the right roofing for your commercial building means looking at factors like durability, fire safety, and cost. This roofing system comparison shows how asphaltic roofing options, like BUR and single-ply, meet different building needs.

Maintenance and Care for Built Up Roofs

Keeping a BUR roof in good shape can make it last longer. Regular checks, upkeep, and fixing problems fast can prevent big costs and downtime. This keeps your business safe and running smoothly.

Routine Inspection

Checking your BUR roof often is key to its long life. Experts suggest inspecting it every five years. Catching issues early means you can fix them before they get worse.

Having inspections twice a year, in the fall and spring, keeps your roof in top shape. This helps spot problems like cracks or blisters early. Fixing these issues quickly keeps your roof strong.

Repair and Replacement

Fixing BUR roofs quickly is important. Small problems fixed fast can stop big repairs or even a full roof replacement. Quick action on leaks or damage keeps your roof waterproof and insulated.

A well-cared-for BUR roof can last 20 to 35 years or more, depending on your area’s weather. Asphalt, a key part of BUR, has been trusted for centuries. Regular repairs keep your BUR roof working well.

BUR roofs are priced between $4 to $10 per square foot. Regular care and checks mean fewer repairs and lower costs over time. This makes BUR a reliable and cost-effective choice for your roof.

Cost Analysis of Built Up Roofing

Looking at the cost of a Built-Up Roof (BUR), we see more than just the upfront price. The initial cost and long-term savings make BUR a smart choice. It’s a solid investment that pays off over time.

Initial Investment

The cost to install a black BUR is about $56,800, or $5.68 per square foot. White BUR is a bit pricier at $57,800 or $5.78 per square foot. These costs cover materials and installation, offering great value from the start.

Long-Term Savings

Over 20 years, BUR systems save a lot of money. A black roof saves $4,000, while a white roof saves $16,000 thanks to its better reflectivity. Maintenance also plays a part in the long-term savings.

Renovations and disposal costs can vary greatly. A black BUR might cost $29,157 for renovations and $9,963 for disposal. But a white BUR avoids these costs, making it a better choice for over 20 years.

After 20 years, the total cost for a black roof is $115,220. For a white roof, it’s much lower at $46,600. This shows the smart choice of investing in BUR, with its upfront costs and long-term savings.

| Roof Type | Initial Cost | Energy Savings (20 years) | Maintenance Cost | Renovation Cost | Disposal Cost | Life Cycle Cost (20 years) |

|---|---|---|---|---|---|---|

| Black BUR | $56,800 | $4,000 | $23,300 | $29,157 | $9,963 | $115,220 |

| White BUR | $57,800 | $16,000 | $5,800 | $0 | $0 | $46,600 |

Weather Resistance and Protection

Built-up roofing systems (BUR) are known for their strength and weather resistance. They protect against harsh weather like strong sun, heavy rain, and strong winds. This makes them perform well under tough conditions. It’s important to keep roofing materials above 50°F and cut them to 18′ or less for the best results.

Using insulating equipment for asphalt is key in cold weather. Following ASTM D312 guidelines for asphalt temperatures ensures the best results. Also, keep cements, adhesives, and coatings in the right temperature with lids on tight to avoid drying out or getting dirty. This helps the roofing materials last longer.

When working in the cold, think about wind, humidity, and sun. Finish each roof section each day to avoid water getting trapped. This is key for the roof’s long life and performance. Built-up roofs can handle extreme weather like heat, cold, snow, and wind without needing to be replaced often.

BUR systems are great at fighting against the elements and save energy by reflecting sunlight. They are also affordable and last a long time with the right care. Built-up roofs can last up to 50 years, showing how reliable they are against different weather.

If it’s too cold to apply roofing materials, seal the system and wait for better weather. Keeping the roof deck clean and wearing the right clothes to avoid accidents is also important for a safe install.

BUR systems are versatile, offering different materials like modified bitumen and asphalt for various budgets and climates. They save money to install and are very resistant to weather, making them a top choice for commercial roofs.

| Key Metrics | Details |

|---|---|

| Material Storage Temperature | > 50°F |

| Maximum Length of Roll Goods | 18′ |

| Types of Asphalt | Types III and IV |

| Lifespan with Proper Maintenance | Up to 50 years |

| Energy Efficiency | Reduces need for air conditioning on hot days |

Sustainability of Built Up Roofs

Built-up roofing (BUR) systems are great for the planet. They last a long time and are good for the environment. Buildings in the U.S. produce nearly half of all greenhouse gases. Using products like Sika Sarnafil helps reduce these emissions and supports green roofing.

Environmental Benefits

BUR systems last 15 to 30 years, sometimes more than 40. This means they need to be replaced less often. This reduces the amount of materials used and waste made.

These roofs also help buildings stay cool or warm efficiently. In hot places, they can cut energy use a lot. The special surfaces on BUR roofs keep the roof cool, which helps save energy.

Ballasted BURs are lighter and cheaper to remove when needed. They can stay in a landfill for up to 15 years, cutting down on waste. Learning what makes roofs sustainable shows how green roofing helps the planet.

Recyclable Materials

BUR uses recyclable materials, like metal parts. Recycling these materials helps the environment. It’s also cheaper and better for the planet. Plus, PVC roofs by Sika don’t catch fire easily and can stop burning on their own, keeping us safe.

New BUR technologies are getting greener all the time. Studies on sustainable roofing show big savings and better environmental impact. Watching energy use and using new energy-saving tech can make BUR even better for the earth.

Source Links

- What Is a Built Up Roof

- Understanding built up roof systems | Roofcorp

- Built-Up Roofing (BUR) Systems

- Design of Built-Up Roofs

- Comprehensive Guide To Built-Up Roofing for Spokane Area

- Roofing Systems | WBDG – Whole Building Design Guide

- Built-Up Roofing: The Advantages and Disadvantages

- The Benefits of Built-Up Roofing (BUR) for Commercial Applications

- What is a Built-up Roofing System?

- Built Up Roof

- A Complete Guide To Built-up Roofs

- What Are Built-Up Roofs? (Materials, Installation, & More) – Rescue My Roof

- A Guide to Built-Up Roofing for Commercial Roofs

- Removing And Replacing A Built-Up Asphalt Roof

- What is a Built-Up Roof and why should I use it?

- No title found

- Built Up Roofing Systems (BUR): Types, Pros, Cons, and Costs

- Single Ply vs Built Up Roofing – Regan Roofing, Inc.

- Built-Up Roof Vs. Modified Bitumen: Which One Is the Best for Commercial Building

- Compared: Built up Roofing vs. Single Ply Roofing

- Guide to BUR (Built-Up Roof) Maintenance and Repairs

- How Long Does a Built-Up Roofing System Last?

- Warehouse Roofing: Maintenance Tips for Longevity – BT Roofing

- Calculating the Life Cycle Cost of a Roof

- Single-Ply Roof Systems – Cost to Own Analysis & Comparison

- Cost Comparison & Analysis – Lafaves Metal Roofing

- Cold Weather Recommendations for Built-Up Roofing – Asphalt Roofing Manufacturers Association (ARMA)

- The Benefits of Built-Up Roofing Systems – Roof Replacement & Roof Repair Specialist in Burlington, Milton, Oakville, Mississauga. Etobicoke, North York, Richmond Hill, & Vaughan

- Built up Roof: Should You Install One? | Viking Contractors LLC

- What Makes A Roof Sustainable

- Built-Up Roofing: Everything You Need To Know

- Sustainable Industrial Roofing: How We Stay Sustainable when Roofing